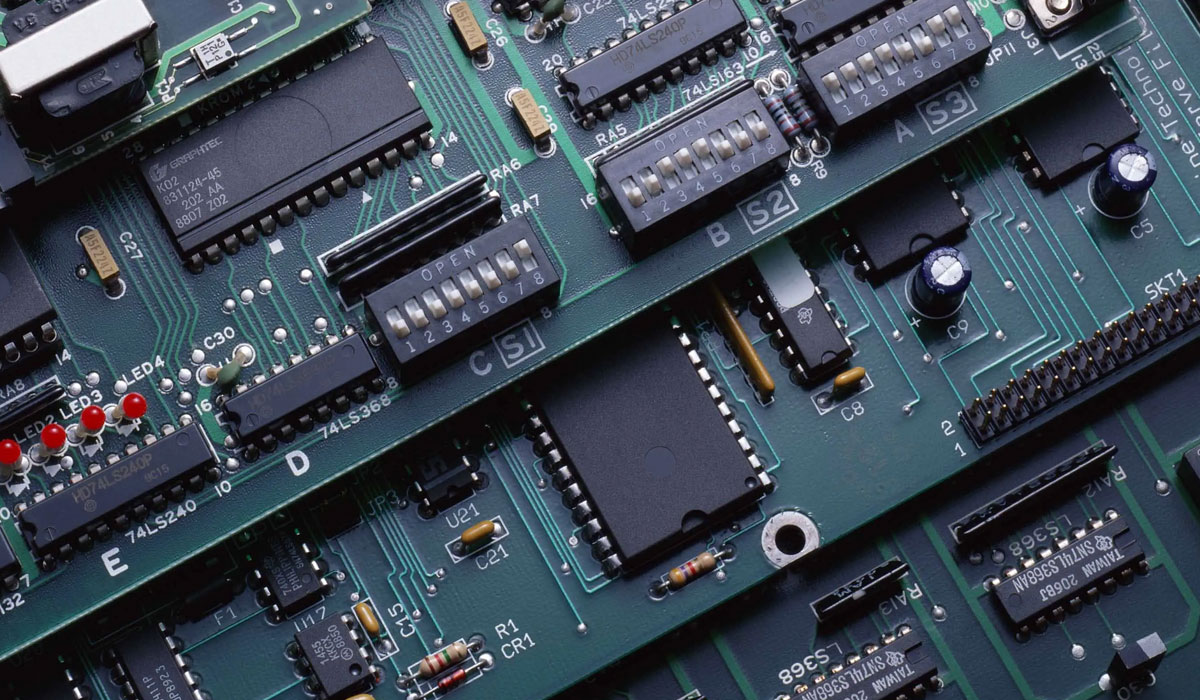

it is known that PCB factories with compLete processes generally have Three dust-free rooms above 100000 level: inner circuit, outer circuit and resistance Welding workshop

Then why does PCB production control the temperature and huMidity of these three workshops? What impact will temperature and humidity have on these three workshops

1. if the temperature is too high, the film will be elongated, and if the temperature is too low, the film will be shoRTened

2. Too high temperature will affect the effective parking time of dry films and inks, as well as the development Quality

4. If the temperature is too high, the water vapor will evaporate more, which will Cause the humidity to beCome higher at the same time. otherwise, the temperature will also decrease if the temperature is low

5. High humidity will cause the film to stretch, while low humidity will cause the film to shorten

The temperature and humidity control of the dust-free room is greatly affected by the air intake and exhaust volume. during the design, the positive pressure, air intake and exhaust volume, the power of the central air conditioner, and the size of the workshop space should be comprehensively Considered, so that the temperature and humidity can be well controlled; Otherwise, the humidity will increase in winter, the humidity will be removed in summer, and the temperature and humidity in the workshop will be uneven

At present, many PCB factories and workshops in China will be equipped with_ Industrial workshop dehumidifiers and PD series Intelligent humidity control dehumidifiers are used to reduce humidity, but the temperature will be too high when they are turned on. The air outlet should be directed to an open place, not to the film or the plate

proper temperature and humidity control is the key to ensure the production and processing safety and quality of electronic Products, ensure the stable operation of mechanical equipment, reduce the frequency of equipment failures, and Extend the service life of equipment. generally, the level of dust-free room in PCB workshop is required to be 100000, the temperature control range is 22+/- 2 degrees, and the humidity control range is 55+/- 5%

Therefore, when the rainy Weather increases and the air humidity increases, how to control the humidity in the PCB processing workshop of the electronic factory within a reasonable range, ensure the processing quality of electronic products, ensure the operating Efficiency of mechanical equipment, and reduce the frequency of equipment failures has always been a very Important issue for the PCB processing enterprises of the electronic factory

and_ Industrial workshop dehumidifier and PD series intelligent humidity control dehumidifier, as professional and efficient dehumidifier and humidity control equipment, help electronic factory PCB processing enterprises effectively solve this problem. All the above contents about dehumidifier in PCB PCB factory and strict control of workshop humidity, Moisture and humidity are provided by Zhengdao Electric, for your reference only